|

|

Home

Tools

Drilling and Fixing

Putting Things Up

Repairs/Maintenance

Plumbing

Electrics

Woodwork

Decorating a Room

Tiling

Safety & Security

Saving Energy

House and Finance

Health&Safety

Disclaimer

Contact

Advertising

Useful Links

Site Map

| Tiling around fiddly areas | ||||||||||||

| This is the trickiest part of tiling but if you take your time, measure and cut carefully, you should be able to get excellent results. | ||||||||||||

|

||||||||||||

Tiling around electrical outlets First, tile as close as you can to the socket/switch. -Use a hand tile saw. |

||||||||||||

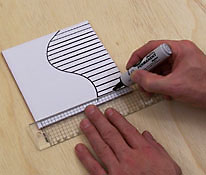

| Making a card template to fit behind socket | ||||||||||||

|

||||||||||||

Using a hand tile saw to cut out shapes. |

||||||||||||

Curved or round shapes Again make a template the size of a tile. Use paper rather than card so that you can easily form the paper around the object to copy the exact shape you need. Transfer the paper template to the tile to mark it then cut out the shape from the tile.

|

||||||||||||

|

||||||||||||

| Folding and cutting paper to form a template round a WC pan | ||||||||||||

|

||||||||||||

| Profile gauge | ||||||||||||

How to cut a curve in tile -Use a hand scribe and nibbler -Use a hand tile saw. |

|

|||||||||||

Using a jigsaw |

||||||||||||

| -Use an electric tile saw. You can get a curve with an electric tile saw with series of straight cuts. Mark out the tile then after making a series of straight cuts with the saw use tile pincers to nibble off each strip. You should be able to nibble a quite tidy edge. If necessary get an smooth line by by finishing with a tile file. |

|

|||||||||||

| Marking straight lines to cut a curve with an electric tile cutter | ||||||||||||

| Tiling round a small pipe To tile round a small pipe will depend on how the tiles are positioned in relation to it. You may only need to take a small section from the side. Or you may have to cut a tile in half and take a semi circle from each part using one of the above methods. Alternatively you could cut out a slit in a whole tile the width of the pipe so the tile slides in. |

||||||||||||